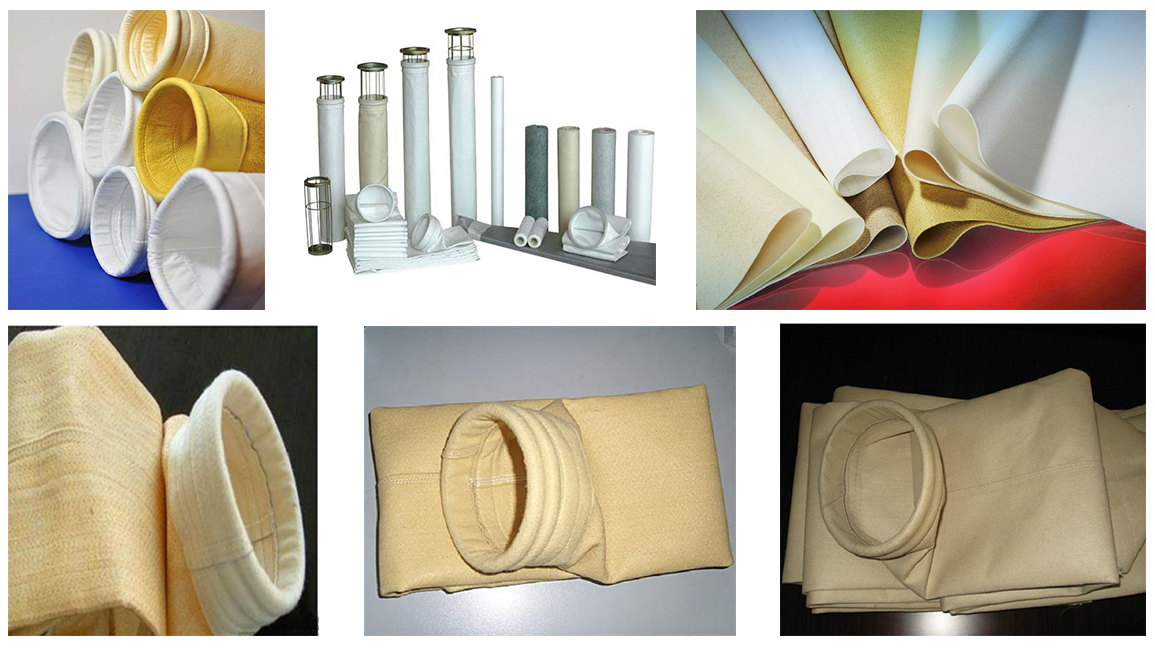

Filter Bags

We manufacture filter bags, filter cages and filter systems. The filter bag, which is indispensable for a cleaner air, is generally used in filter cabinets called jet pulse.

How do we choose filter bags?

The most important factor in determining the filter bag type is temperature. The higher the temperature at which the industry has worked, the higher the necessity of using a temperature resistant bag. Another factor in filter bag selection is acid, alkali, hydrolysis, solvent and oxide resistance. These parameters are important in determining the bag type according to the needs of the sectors. Bag types and temperature resistance values are given below.

Filter Bag Materials

Bags used in de-dusting and filtering systems are produced depending on operation conditions using felt fabrics made of %100 Polyester, %100 Polypropylene, %100 Homopolymere Acrylic (Dolanit), %100 Copolymer Acrylic, %100 Ryton (Polyphenylsulfide),%100 Meta-Aramid (Nomex),%100 Polyimide (P-84),%100 Teflon (PTFE), %100 Fibre glass and their quality is in accordance with European Norms.

Polyester Filter Bags

General Information

Polyester needle felt filter bag is a material commonly used in bag filter systems. Polyester filter bag is preferred because of its low cost and its smooth operation under many sectoral conditions. In particular, its solvent and oxide resistance is high, but its acid resistance is also moderate. There are weight values such as 400, 500, 525, 550, 600 grams per square meter. The filter bag, whose content is 100% polyester, is internally textured and resistant to tensile and tensile stress.

By using the needling method in its manufacture, the fiber polyester material is turned into fabric and then dipped into hydrophobic liquids in order to gain water and oil repellency. Therefore, it is also called needle felt filter bag. The polyester filter bag, which becomes bright and smooth as a result of gassing on one side, ensures that the dust does not hold on. The moist and oily powder coming to the bag system is easily poured down with the help of pulses without holding onto the bag.

Polyester filter bags with a continuous operating temperature of 150 degrees work without any problems in sectors operating at normal temperatures. However, it is necessary to use bags such as nomex filter bags and P84 filter bags in systems operating at high temperatures and where the incoming air and dust are at a level that can melt the bags. Çözüm Filter A.Ş., an expert in the filtration sector. Do not forget to contact us to get detailed information about filter bags, which will be determined by the engineers according to the sector conditions.

You can get support from us on what material should be the material to be attached to your bag system, with the experience and expertise of many years in filtration. In case of need, we can come to your business site and make examinations and help determine the type of bag. Our solution team will guide you correctly based on the following points in determining the bag material:

- Sector

- The distance of the filter system to the production site

- Filter system capacity

- The temperature and dryness of the dust coming into the system.

Usage Area

- 150°C Polyester filter bags with a continuous operating temperature of 150°C are preferred in many sectors.

- Low Cost It is preferred because of its low cost and smooth operation in many sectors. Polyester filter bags providing high resistance to acids and oxides are strong against abrasion.

By applying hydrophobic impregnation, you can easily use the polyester filter bag, which has water and oil repellent properties, in sectors where dust comes in water and oily form. Bags with a gauze on one side prevent the dust from clinging to the bag by sliding easily from the surface.

Specifications of Polyester Filter Bags

| Content | 100% POLYESTER |

| Inner tissue | POLYESTER |

| Weight | 525 g/m² ± %5 |

| Air permeability | 11.000 – 14.000 lt/dm²/hour (Dp:200 Pa) |

| Thickness | 2.0 mm |

| Breaking strength | Longitudinally: 150 kgf/5 cm - Transverse: 190 kgf/5 cm |

| Surface treatment | CALENDERED AND GLAZED, WATER AND OIL REPELLENT |

| Operating temperature | CONTINUOUS 150°C DRY TEMPERATURE |

| Acid resistance | |

| Alkali resistance | |

| Hydraulic resistance | |

| Solvent resistance | |

| Oxid strength |

Meta aramid (NOMEX) filter bags

General Information

Nomex filter bag should be preferred in sectors such as iron and steel melting plants operating at high temperatures, asphalt plants. This is because polyester filter bags can work at 150 degrees, while nomex (meta-aramid) filter bags work continuously at 200 oC.

The main material of this filter bag, known as nomex in the industry, is meta-aramid. This material, developed by Dupont, is sold under the Nomex® brand. Nomex (meta-aramid) products are produced in a way that does not melt, drip and does not catch fire in contact with air.

Acid, alkali and hydrolysis strengths are moderate, solvent and oxide strengths are good. It has variable weights between 400-525 grams per square meter and, like all other bags, it has hydrophobic impregnation application with water and oil repellent feature. Nomex filter bag is preferred in power plants and factories such as asphalt plants, ceramic, metal, waste enterprises, cement & lime plants, coal plants, power plants, foundries.

Many parameters are important in determining the most suitable material for the bag filter system. The most important of these is the degree of hot air and dust coming into the system. The operation of Nomex filter bags at 200 degrees is important for the sectors mentioned above. Polyimide P84 Filter Bag is recommended in sectors operating at a higher degree and in systems where the temperature of the air and dust coming into the system is higher due to the fact that the bagged systems are close to the operation area. The continuous operating temperature of these bags is 260 degrees and works smoothly in high temperature conditions.

Usage Area

- HIGH TEMPERATURES..In sectors with high temperatures such as iron and steel melting plants, asphalt plants, a high temperature resistant filter bag is needed to prevent the bags from melting with the incoming hot dust and air.

- 200°C..In order to meet this need, meta-aramid Nomex filter bags with a continuous operating temperature of 200°C (instantaneous maximum temperature 220°C) should be preferred.

Otherwise, the use of polyester filter bags that are resistant to lower temperatures will cause the bags in the system to melt

Specifications of Meta aramid (NOMEX) filter bags

| Content | 100% meta-aramid (nomex) |

| Inner tissue | Meta-aramid (nomex) |

| Weight | 400-525 g/m² ± %5 |

| Air permeability | 11.000 – 14.000 lt/dm²/hour (Dp:200 Pa) |

| Thickness | 1.8 mm |

| Breaking strength | Longitudinally: 110 kgf/5 cm - Transverse: 140 kgf/5 cm |

| Surface treatment | Calendered and glazed, water and oil repellent |

| Operating temperature | Continuous 200°c dry temperature |

| Acid resistance | |

| Alkali resistance | |

| Hydraulic resistance | |

| Solvent resistance | |

| Oxid strength |

Antistatic Filter Bag

General Information

The production of antistatic filter bags is extremely important, especially because of the danger of dust generated in some sectors such as plastic and flour coming into the system under electrical charge. Although polyester filter bag products can be used in every sector, some sectors cause fires in the system as a result of dust and air reaching the system under electrical charge. Therefore, antistatic bag filters have been manufactured in order to make dust and air safe as a result of electrostatic studies. In this way, the possibility of fire has been eliminated and the focus is on the healthy operation of the system.

It prevents such dangers by being manufactured as conductive rods or conductive fiber strips placed in the bag. Antistatic filter bag production is carried out in this way and both the bags and the filter system are protected thanks to the conductive rods and the business continues production without any problems.

Usage Area

- Cement Factories

- Metal Processing Plants

- Wood Factories

- Grain Warehouses

- Fertilizer Plants

- Quarries

- Plaster Factories

- Melting Plants

- Polishing Plants

- Lead Factories

Antistatic bag filters are mainly used in the following sectors, and may vary depending on the enterprise and raw material where the production is made. Therefore, it is important that you provide information in advance by contacting our expert team in the selection of the filter bag.

In the sectors mentioned above, there are situations where dust can come to the system electrically. Therefore, it is extremely important to choose the bag filter correctly during and after the installation of the filter system. Filter system capacity, location, sector, raw material processed, temperature, oxide, solvent etc. information about the values are obtained and bag selection is determined accordingly.

Specifications of Antistatic Filter Bag

| Content | 100% Polyester Antistatic |

| Inner tissue | Polyester Antistatic |

| Weight | 550 G/M² ± %5 |

| Air permeability | 4.000 Lt/Dm²/Hour (Dp:200 Pa) |

| Thickness | 2.5 mm |

| Breaking strength | Longitudinally: 110 Kgf/5 Cm - Transverse: 140 Kgf/5 Cm |

| Surface treatment | Calendered And Glazed, Water And Oil Repellent |

| Operating temperature | Continuous 130°C Dry Temperature |

| Acid resistance | |

| Alkali resistance | |

| Hydraulic resistance | |

| Solvent resistance | |

| Oxid strength |

PTFE (Teflon) Filter Bag

General Information

PTFE (teflon) filter bag is a type of bag used for sectors operating at high temperatures thanks to its 260 ° C continuous operating temperature. Acid, alkali, hydrolysis, solvent and oxide grades are also excellent, and PTFE (teflon) filter bag is preferred in sectors where dust has aggressive properties. Although polyester filter bag products can be used in every sector, PTFE (teflon) filter bags must be used in some sectors due to the high chemical properties of dust and air. Therefore, the selection of a filter bag is very important for dust with very dense chemical properties and high temperature. In this way, the filter system is provided to work properly by preventing the bags from piercing and losing the bag feature.

Hydrophobic impregnation process is applied to PTFE (teflon) filter bag to give water and oil repellency and although the dust is moist, it does not stick on the bag and the air flow is provided to proceed smoothly. In addition, one side of the bag is gassed so that the dust easily slips over the bag.

Usage Area

- Chemical Properties.. PTFE (teflon) filter bag is mainly used in sectors where the chemical properties of the dust are high and at high temperatures, and it may vary according to the enterprise and raw material where it is produced. Therefore, it is important that you provide information in advance by contacting our expert team in the selection of the filter bag.

Filter system capacity, location, sector, raw material processed, temperature, oxide, solvent etc. Information about the values is obtained from the company and bag selection is determined accordingly. Thus, possible accidents that may occur later are prevented and it is ensured that the production is not interrupted.

Specifications of PTFE (Teflon) Filter Bag

| Content | 100% Ptfe |

| Inner tissue | Multifilament Ptfe |

| Weight | 750 G/M² ± %5 |

| Air permeability | 11.000 – 14.000 Lt/Dm²/Hour (Dp:200 Pa) |

| Thickness | 2.0 mm |

| Breaking strength | Longitudinally: 150 Kgf/5 Cm - Transverse: 190 Kgf/5 Cm |

| Surface treatment | Calendered and Glazed, Water And Oil Repellent |

| Operating temperature | Continuous 260°C Dry Temperature |

| Acid resistance | |

| Alkali resistance | |

| Hydraulic resistance | |

| Solvent resistance | |

| Oxid strength |

PP Polypropylene Filter Bag

General Information

Polypropylene Filter Bag (PP Filter) is a type of bag used for sectors operating at low temperatures with a continuous operating temperature of 90 ° C. It is preferred in sectors with high acidic and basic properties. Polypropylene Filter Bag (PP Filter), which is perfectly resistant to acids and bases, is used in the chemical industry, filtration of process fluids, food industry, metal coating filtration processes, etc. It is used in industries.

By applying a hydrophobic impregnation process to the Polypropylene Filter Bag (PP Filter), it gains water and oil repellency, and although the dust is moist, it does not stick on the bag and the air flow is provided smoothly. In addition, one side of the bag is gassed so that the dust easily slips over the bag.

Usage Area

- Chemical industry

- Filtration of process fluids

- Food industry

- Metal coating filtration processes.

Polypropylene Filter Bag (PP Filter) is mainly preferred in sectors where the acidic and basic properties of the dust are high. Therefore, it is important that you provide information in advance by contacting our expert team in the selection of the filter bag.

These sectors are mainly;

Filter system capacity, location, sector, raw material processed, temperature, oxide, solvent etc. Information about the values is obtained from the company and bag selection is determined accordingly. Thus, possible accidents that may occur later are prevented and it is ensured that the production is not interrupted.

Specifications of PP Polypropylene Filter Bag

| Content | 100% Polyester |

| Inner tissue | Polypropylene |

| Weight | 525 G/M² ± %5 |

| Air permeability | 9.000 Lt/Dm²/Hour (Dp:200 Pa) |

| Thickness | 2.0 mm |

| Breaking strength | Longitudinally: 110 Kgf/5 Cm - Transverse: 140 Kgf/5 Cm |

| Surface treatment | Calendered And Glazed |

| Operating temperature | Continuous 90°C Dry Temperature |

| Acid resistance | |

| Alkali resistance | |

| Hydraulic resistance | |

| Solvent resistance | |

| Oxid strength |

Fiber Glass Filter Bag

General Information

Glass Fiber Filter Bag is the filter bag that withstands the highest temperature in filter bags. It works smoothly in the working environment up to 275 degrees.

Glass fiber filter bag, which has excellent solvent and oxide resistance, should be preferred in operating conditions that host these chemicals. The filter bag with a weight of 770 grams per square meter, like other filter bags, passes through hydrophobic impregnation and gaseous processes, allowing the air and dust coming into the filter system to be easily collected. Thanks to these processes, the filter bag is prevented from clogging in the system and helps it to have a long life. Element Filter, positioning itself in the upper segment of the market among filter cloth manufacturers, offers you guaranteed technical support before, during and after production.

Usage Area

- Very High Temperatures... When we look at the usage areas of the glass fiber filter bag, there are factories and workshops that need to work at very high temperatures. In addition, the chemical values of the air and dust coming into the system gain importance.

In order to choose a healthier filter cloth, you can get information from our expert and experienced team. You can be sure that we will give you the most accurate information depending on the environment and conditions of your business.

Specifications of Fiber Glass Filter Bag

| Content | 100% Glass Fiber |

| Inner tissue | Glass Fiber |

| Weight | 770 G/M² ± %5 |

| Air permeability | 3.000 – 4.000 Lt/Dm²/Hour (Dp:200 Pa) |

| Thickness | 2.0 mm |

| Breaking strength | Longitudinally: 150 Kgf/5 Cm - Transverse: 120 Kgf/5 Cm |

| Surface treatment | Calendered and Glazed |

| Operating temperature | Continuous 275°C Dry Temperature |

| Acid resistance | |

| Alkali resistance | |

| Hydraulic resistance | |

| Solvent resistance | |

| Oxid strength |

Polyimide P84 Filter Bag

General Information

100% Polyimide ( P -84 ) is the best known filtering material for heat resistant industrial filtration.

Polyimide, also known as P84, is a state-of-the-art filtration material that maintains its filtering feature at high temperature [instant max 260°C]. Chemical and temperature resistance is quite good. It has higher properties than all needle felt filtration materials except polyimide PTFE. It has non-flammable properties with fibers with a very low limit oxygen index. High performance can be obtained in Fluorocarbon systems with moist and sticky dusts with different surface treatments.

Usage Area

- Power Plants

- Cement Factories

- Limestone Industry

- Waste Incineration

- Steel casting industry

- Combustion Plants Filter

- Medical Disposal Facilities Filter

- Waste Incinerators Filter

Polyimide P84 filter bags are used in various industries. Some of them are:

Specifications of Polyimide P84 Filter Bag

| Content | 100% POLYIMIDE (P84) |

| Inner tissue | POLYIMIDE (P84) |

| Weight | 525 g/m² ± %5 |

| Air permeability | 9.000 – 11.000 lt/dm²/hour (Dp:200 Pa) |

| Thickness | 2.0 mm |

| Breaking strength | Longitudinally: 130 kgf/5 cm - Transverse: 170 kgf/5 cm |

| Surface treatment | Calendered and Glazed |

| Operating temperature | Continuous 260°C Dry Temperature |

| Acid resistance | |

| Alkali resistance | |

| Hydraulic resistance | |

| Solvent resistance | |

| Oxid strength |

Download PDF Datasheet

Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris.

Download PDF