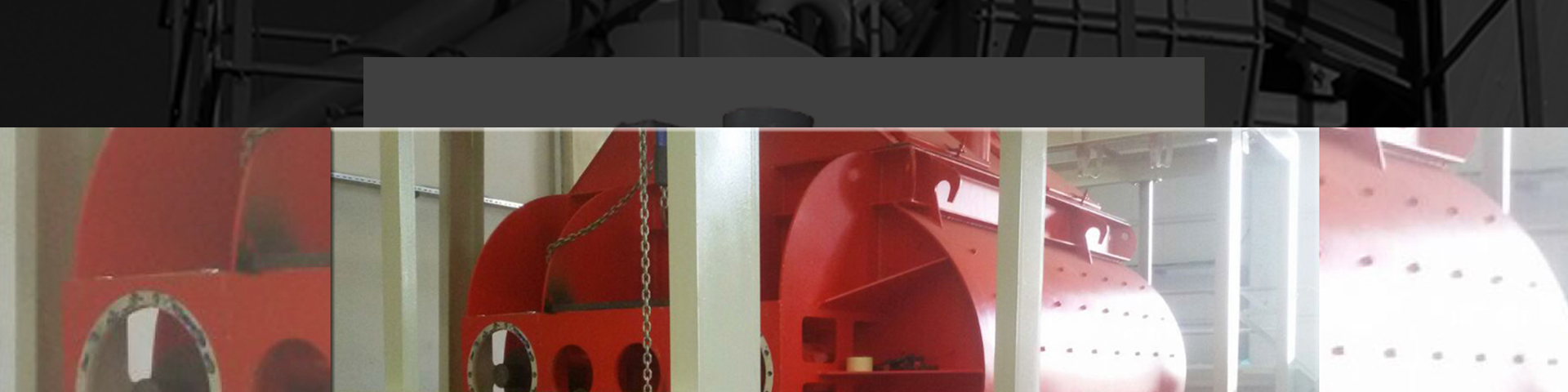

TWINSHAFT MIXERS

Twinshaft Concrete Mixer are designed for strength and abrasion resistance. The design, quality and paddle structures of these mixers are robust and provides long life

HIGH CAPACITY AND EFFICIENCY

Twinshaft Mixers' bearings, sealings, lubrication system and used abbrasive resistant linings are the guarantee of long-life.

COMPONENTS & OPTIONALS

- Top-cover -provide wide and easy maintenance access

- Water distribution system-included according to applciaiton type

- Discharge gate -hydraullically driven and equipped with sensors

- Maintenance platform -mixer group can be equipped with maintenance platform

- Sensors -mixer can be equipped with temperature, safety, moisture sensors

SPECIFICATIONS

| Description | Unit | CRM-2,0mt | CRM-3,0mt | CRM-4,5mt |

|---|---|---|---|---|

| Capacity | m3 | 2,0 | 3,0 | 4,5 |

| Motor | Kw | 2x37 | 2x55 | 2x90 |

| Wearing plates - side body | - | ST52 | ST52 | ST52 |

| Wearing plates - main body | - | NiHard | NiHard | NiHard |

| Wearing plates - shaft&paddles | - | NiHard | NiHard | NiHard |

| Automatic Lubrication System | - | Yes | Yes | Yes |

| Water Distribution | - | Yes | Yes | Yes |

| Hydraulic Discharge Gate | - | Yes | Yes | Yes |

| Maintenance Door Safety Switch | - | Yes | Yes | Yes |

| Emergency Stop Button | - | Yes | Yes | Yes |

Thick special cast linings, paddle structure, high quality bearings and seals are features that differentiates OPT Makine mixers from others'.